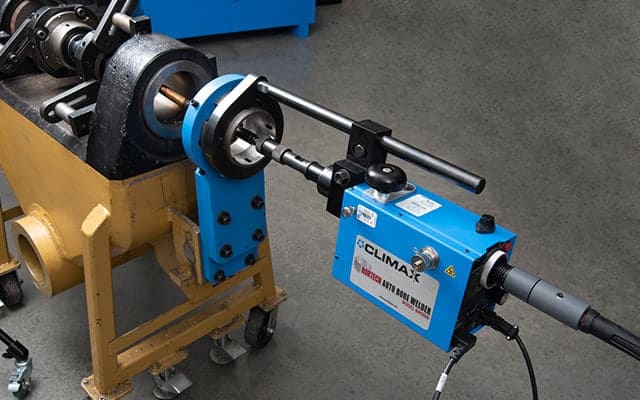

BW2600 Auto Bore Welder

Is a compact blend of simplicity, performance, and reliability, capable enough to tackle aggressive field applications with ease. The BW2600 interfaces directly with users existing MIG Wire feed systems, providing Skip / Fill capability with burn back control for these functions, fully adjustable mechanical step, reversible weld direction, step lockout feature for face welding and optional remote pendant control.

Axial Travel: 9 inches (228.6 mm)

Wire Diameter Range: 0.030 – 0.045 inches (0.76 – 1.14 mm)

Step Range/Pitch: Step Range: 0.050 – 0.175 inches (1.27 – 4.45 mm) per rev

Rotational Direction: Reversible

Auto-Skip: Skip / Fill

Standard Torch Range: 0.88 – 5 inches (22.4 – 127 mm)

HIGH QUALITY AND PRECISION

Swivel head provides torch adjustment through a simple and robust ball and seat arrangement, the simplest design in the industry.Automated skip / fill is a simple cam operated feature that allows the operator to easily program WELD ONLY or NO WELD sections of the bore up to 180 degrees. Simply set the cams and the machine takes care of the rest. Machine fully rotates between skip / fill sections.

Reverse Rotation allows the operator to reverse the rotation direction. This is typically used when the bore welder is in the horizontal axis and the operator needs to weld multiple passes. This feature alternates the uphill weld over the downhill weld of the last complete pass, simplifying multi-pass welding.

Hand held pendant allows operator to control welder operations from one hand held control panel. Rotation jog, weld stop/start, arc interrupt, and rotation speed.

FLEXIBLE AND VERSATILE

Free position allows the operator to move the spindle freely for torch placement, or move the spindle quickly to change consumables when the need arises.Adjustable step feed allows adjustability of bead placement and eliminates weld void at ends of weld.

Run mode allows the operator to move the spindle with the worm gear knob, allowing incremental fine adjustment of the axial start point, or when small adjustments are needed when welding.

Step lock-out allows the ability to face weld, greatly expanding the versatility of the welder. This feature also allows operators to reduce or eliminate axial feed for the first or last passes.

Boring Bar Interface Kit allows quick alignment and attachment of the BW2600 to CLIMAX Line Boring Systems for quick turnover between welding and boring for fast completion of jobs.

Adjustable base allows mounting of the BW2600 to fit any workpiece when not using a boring bar. The non-magnetic mounting base makes welding in job shops, machine shops, or specialized applications simple and easy.

SAFETY

Free position allows the operator to move the spindle freely for torch placement, or move the spindle quickly to change consumables when the need arises.Adjustable step feed allows adjustability of bead placement and eliminates weld void at ends of weld.

Run mode allows the operator to move the spindle with the worm gear knob, allowing incremental fine adjustment of the axial start point, or when small adjustments are needed when welding.

Step lock-out allows the ability to face weld, greatly expanding the versatility of the welder. This feature also allows operators to reduce or eliminate axial feed for the first or last passes.

Boring Bar Interface Kit allows quick alignment and attachment of the BW2600 to CLIMAX Line Boring Systems for quick turnover between welding and boring for fast completion of jobs.

Adjustable base allows mounting of the BW2600 to fit any workpiece when not using a boring bar. The non-magnetic mounting base makes welding in job shops, machine shops, or specialized applications simple and easy.