the

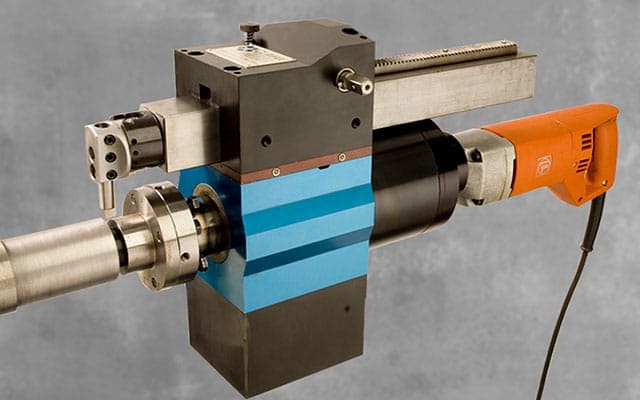

PL3000 LATHE

Re-turns large shafts and roll journals by mounting directly to the work piece and rotating around the shaft. Ruggedly dependable, accurate and powerful, it can eliminate hours of equipment dismantling. Designed for shaft diameters from 4 to 11.25 inches (101.6 to 285.8 mm).Specifications:

Max. Turning Reach: 22 inches (558.8 mm)Shaft Diameter: 4 – 11.25 inches (101.6 – 285.8 mm)

Power Option: Electric or Pneumatic

Product Advantages

Heavy duty, powerful, precise

Heavy solid steel turning bar and counterbalanced body provide smooth turning and minimum chatter, even with the turning bar at maximum reach.

The motor and planetary ring gear drive provide enough torque to remove up to 0.125 inch (3.175 mm) of metal so you can get the job done fast.

A 3.08 Hp (2.3 kW) electric motor and a 1.22 Hp (0.91 kW) pneumatic motor is available.

Tool reach is 16.0 inches (406.4 mm) from end of shaft, and up to 22.0 inches (558.8 mm) with optional turning bar extension.

Turns shafts from 4.0 – 11 inches (101.6 – 279.4 mm). (This machine works within a 16.75 inch (425.5mm) diameter space around the shaft (swing diameter), and 36 inches (914.4 mm) from the end of the shaft.)

Automatic axial feed is variable from 0.003 – 0.011 inches/rev. (0.076 – 0.279 mm/rev.) in 7 increments.

The motor and planetary ring gear drive provide enough torque to remove up to 0.125 inch (3.175 mm) of metal so you can get the job done fast.

A 3.08 Hp (2.3 kW) electric motor and a 1.22 Hp (0.91 kW) pneumatic motor is available.

Tool reach is 16.0 inches (406.4 mm) from end of shaft, and up to 22.0 inches (558.8 mm) with optional turning bar extension.

Turns shafts from 4.0 – 11 inches (101.6 – 279.4 mm). (This machine works within a 16.75 inch (425.5mm) diameter space around the shaft (swing diameter), and 36 inches (914.4 mm) from the end of the shaft.)

Automatic axial feed is variable from 0.003 – 0.011 inches/rev. (0.076 – 0.279 mm/rev.) in 7 increments.

Quick and easy to set up

Mounts on the end of the shaft. Simply remove the gear or bearing to expose the end of the shaft.

The PL3000 can be set up by an experienced operator in less than an hour. Drill and tap four mounting holes on the end of the shaft to attach the tapered mounting flange.

Adjusting screws allow accurate centering and alignment even if the shaft face is no longer square.

The PL3000 can be set up by an experienced operator in less than an hour. Drill and tap four mounting holes on the end of the shaft to attach the tapered mounting flange.

Adjusting screws allow accurate centering and alignment even if the shaft face is no longer square.

Downloads