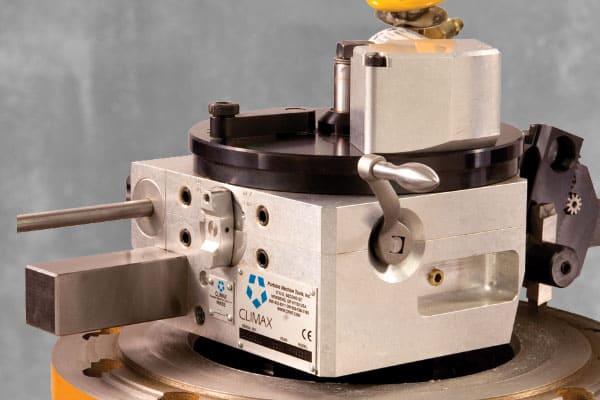

FF4000 FLANGE FACER

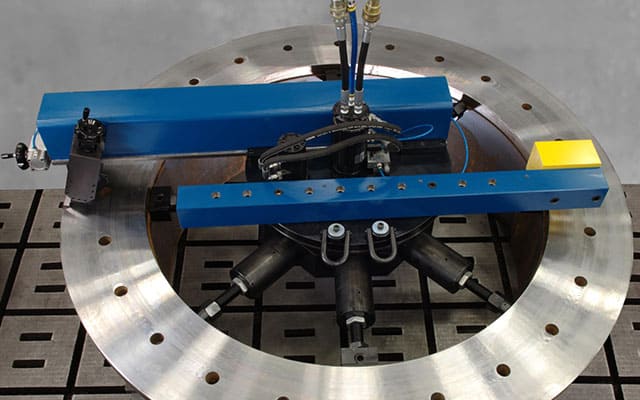

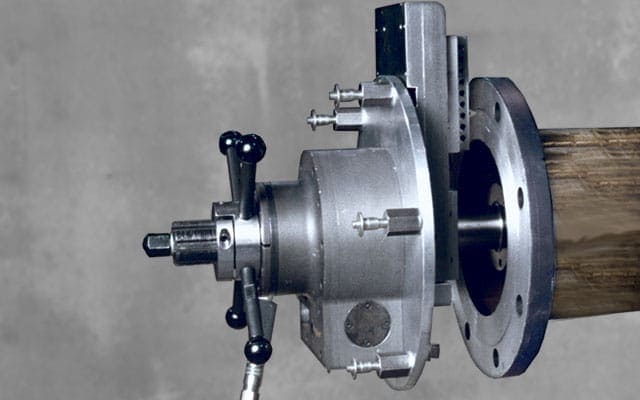

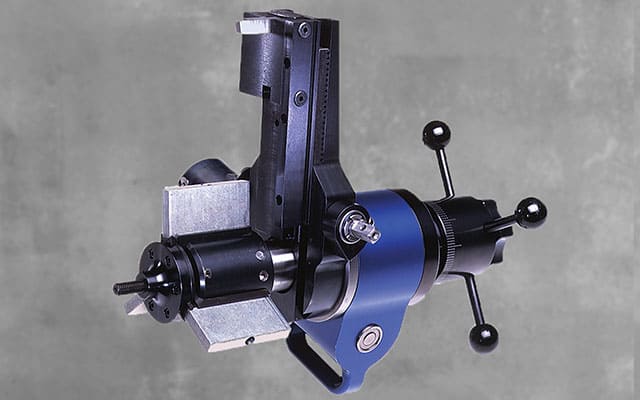

Designed for machining mid-sized diameter raised face and flat pipe flanges or beveling pipe with optional beveling head. Sets up in less than 10 minutes and delivers enough power to remove one cubic inch of metal per minute. Facing diameters range from 3 to 19 inches (76.2 to 482.6 mm).Specification:

Facing Diameter: 3 – 19 inches (76.2 – 482.6 mm)Milling Diameter: N/A

ID Mounting Diameter: 3 – 12.5 inches (76.2 – 317.5 mm)

OD Mounting Diameter: N/A

Power Option: Pneumatic

Product Advantages

Compact and Versatile

Low profile machine is one of the most compact on the market today.

Lightweight, weighing only 58 lbs (26.3 kg).

Modular design and versatile setup allows the chuck and main body to be set up separately before placement in the bore.

Machine raised and flat flanges.

Bi-directional feed.

Feed is reversible and infinitely variable for a surface finish of 63 – 500 RMS.

Optional beveling head connects with “Quick-Lock” system, making changeover quick & easy.

Lightweight, weighing only 58 lbs (26.3 kg).

Modular design and versatile setup allows the chuck and main body to be set up separately before placement in the bore.

Machine raised and flat flanges.

Bi-directional feed.

Feed is reversible and infinitely variable for a surface finish of 63 – 500 RMS.

Optional beveling head connects with “Quick-Lock” system, making changeover quick & easy.

Powerful, Quality Components

1.45 Hp (1.08 kW) motor allows typical material removal rate of 1 cubic inch (16.4 cm3) per minute.

Pneumatic motor comes complete with filter, lubricator, and flow control.

Features rugged main body, heavy-duty bearings, sealed lubrication, and rigid mounting system.

Pneumatic motor comes complete with filter, lubricator, and flow control.

Features rugged main body, heavy-duty bearings, sealed lubrication, and rigid mounting system.

Cost Effective

Cuts costs in four ways:

– Reduces downtime.

– Eliminates off-site machining costs.

– Eliminates leak sealing procedures.

– Reduces stock of replacement flanges.

Recoup the cost of a CLIMAX Flange Facer in the first few flange facing jobs.

– Reduces downtime.

– Eliminates off-site machining costs.

– Eliminates leak sealing procedures.

– Reduces stock of replacement flanges.

Recoup the cost of a CLIMAX Flange Facer in the first few flange facing jobs.

Downloads

LITERATURE DOWNLOAD

OPERATING MANUAL