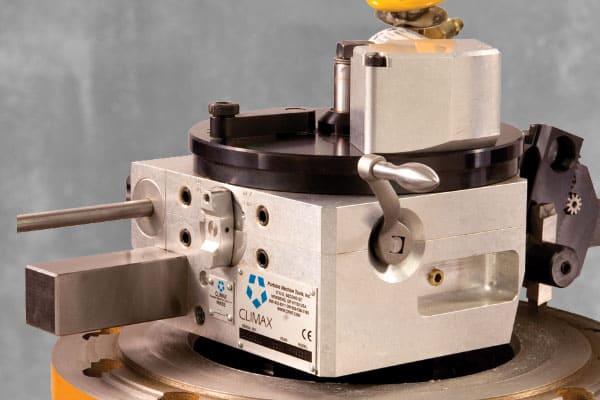

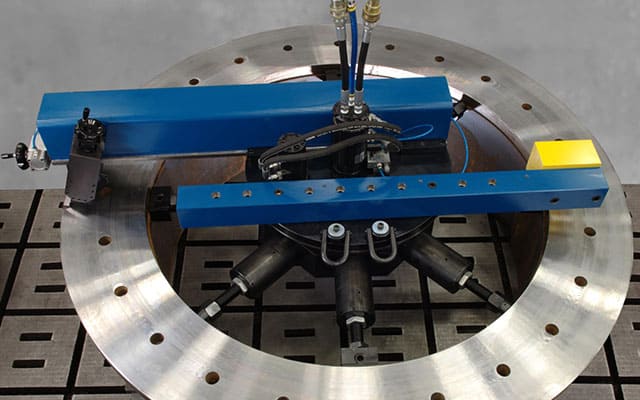

A heavy-duty flange facer with both facing AND milling capabilities.

The FF7200 Flange Facer

features a tool head that rotates a full 360 degrees, infinitely variable feed rates, and remotely adjustable feed so radial and axial feeds can be done quickly and safely. Facing diameters from 30 to 72 inches (762 to 1828.8 mm), milling diameters from 35 to 72 inches (889 to 1828.8 mm).Specification:

Facing Diameter: 30 – 72 inches (762 – 1828.8 mm)Milling Diameter: 35 – 72 inches (889 – 1828.8 mm)

ID Mounting Diameter: 30 – 72 inches (762 – 1828.8 mm)

OD Mounting Diameter: N/A

Power Option: Pneumatic or Hydraulic

Product Advantages

Rugged Machine Design

Large, heavy-duty construction-grade bearings provide powerful, rigid performance throughout the entire machine facing range, even machining over bolt hole patterns.

Oversized ring gear accommodates extremely high torque levels for challenging flange repair applications, and these machines are able to generate a phonographic finish.

Oversized ring gear accommodates extremely high torque levels for challenging flange repair applications, and these machines are able to generate a phonographic finish.

Flexible and Versatile

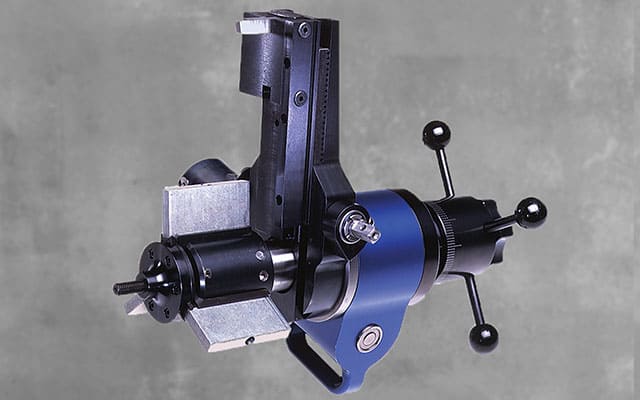

Both radial and axial feed is achieved with a pneumatic feedbox. Manual feeding for rapid positioning is also possible.

Feed rate is adjusted remotely at the pneumatic conditioning unit, providing the ultimate in operator safety and the flexibility for feed rate adjustments even during machining operations.

Infinitely variable feed rates from 0.002-0.035 in. (0.05 – 0.89 mm)/rev provides operational flexibility.

Reversible feed box can be mounted to provide either radial or axial feed.

Turning and counterweight arms can both be adjusted for the desired swing clearance and machining range.

Pneumatic & hydraulic drive options available.

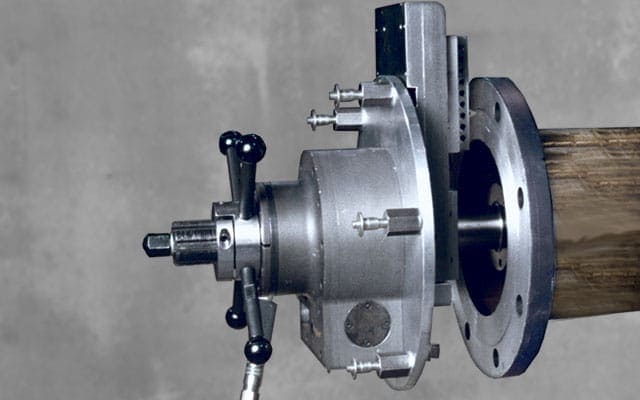

Chucking system can be removed to allow the flange facer to be face-mounted.

Tool head can be rotated a full 360˚ providing the ability to create a variety of chamfers, O-Ring grooves, lens rings and other angular surfaces as needed.

Can be mounted ID or surface-mounted. Call for custom OD mounting options. Grinding option available for fine finish work.

Back facing attachment available for heat exchanger repair.

Feed rate is adjusted remotely at the pneumatic conditioning unit, providing the ultimate in operator safety and the flexibility for feed rate adjustments even during machining operations.

Infinitely variable feed rates from 0.002-0.035 in. (0.05 – 0.89 mm)/rev provides operational flexibility.

Reversible feed box can be mounted to provide either radial or axial feed.

Turning and counterweight arms can both be adjusted for the desired swing clearance and machining range.

Pneumatic & hydraulic drive options available.

Chucking system can be removed to allow the flange facer to be face-mounted.

Tool head can be rotated a full 360˚ providing the ability to create a variety of chamfers, O-Ring grooves, lens rings and other angular surfaces as needed.

Can be mounted ID or surface-mounted. Call for custom OD mounting options. Grinding option available for fine finish work.

Back facing attachment available for heat exchanger repair.

Quick and Easy Setup

Modular design allows many of the machine components to be removed to facilitate easier setup and storage.

Unique chucking system minimizes parts to greatly simplify machine setup and tear down.

Quick-adjust leveling feet make setup quick and easy.

Unique chucking system minimizes parts to greatly simplify machine setup and tear down.

Quick-adjust leveling feet make setup quick and easy.

Downloads

LITERATURE DOWNLOAD

OPERATING MANUAL