The model

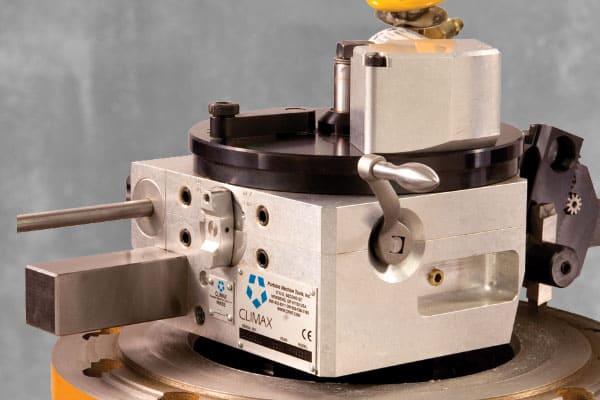

MSF Flange Facer

resurfaces flanges from 1.25 inches ID to 6.19 inches OD (31.8 to 157.2 mm) quickly and accurately. Works with our BG50 BOILER GUN™ for quick and easy conversion between beveling and flange facing in the field.Specification:

Facing Diameter: 1.25 in. ID – 6.19 in. OD (31.8 – 157.2 mm)ID Mounting Diameter: 1 – 5 in. (25.4 – 127 mm) Feed Rate 0.005 in. (0.13 mm) per pin

Power Option: Pneumatic or electric

Product Advantages

Simple, Safe, Accurate Flange Facing

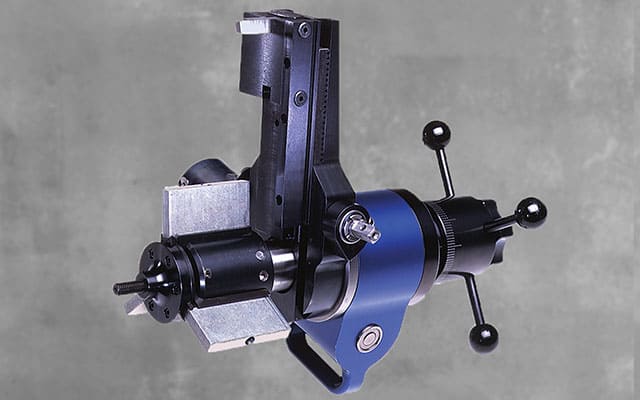

The H&S TOOL Model MSF Flange Facer is a versatile flange facer designed for flanges ranging from 1.25 inches ID to 6.19 inches OD (31.8 to 157.2 mm). The MSF is a reliable pipe machine tool with a premium flange facing conversion kit. Powered by reliable pneumatic or electric motors to accurately meet your job site or shop requirements.

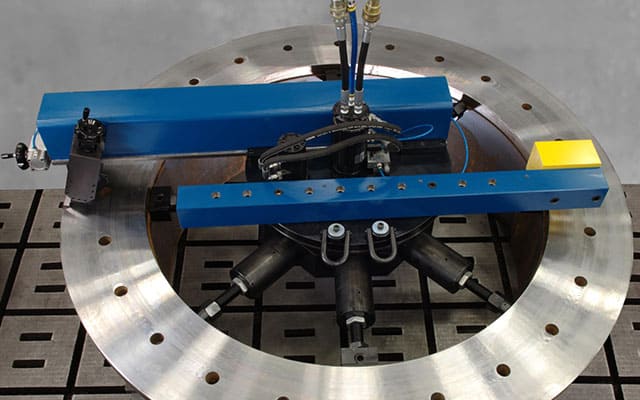

The Model MSF is portable, making it ideal for use in the field. Setup and operation is easily handled by a single worker.

Kits include everything necessary to convert your beveling tool with illustrated instructions.

Standard wedge plates can be used for internal locking or precision elbow mandrels are available. The mandrels are designed to mount in short-radius elbows.

The minimum straight depth to mount the model MSF is 0.5000 inch (12.7 mm). Centering and squaring the device makes accurate machining of gasket surfaces and/or bolt patterns simple and safe.

The minimum straight depth to mount the model MSF is 0.5 inch (12.7 mm).

Centering and squaring devices make accurate machining of gasket surfaces and/or bolt patterns simple and safe.

The Model MSF is portable, making it ideal for use in the field. Setup and operation is easily handled by a single worker.

Kits include everything necessary to convert your beveling tool with illustrated instructions.

Standard wedge plates can be used for internal locking or precision elbow mandrels are available. The mandrels are designed to mount in short-radius elbows.

The minimum straight depth to mount the model MSF is 0.5000 inch (12.7 mm). Centering and squaring the device makes accurate machining of gasket surfaces and/or bolt patterns simple and safe.

The minimum straight depth to mount the model MSF is 0.5 inch (12.7 mm).

Centering and squaring devices make accurate machining of gasket surfaces and/or bolt patterns simple and safe.

Downloads

LITERATURE DOWNLOAD

OPERATING MANUALS