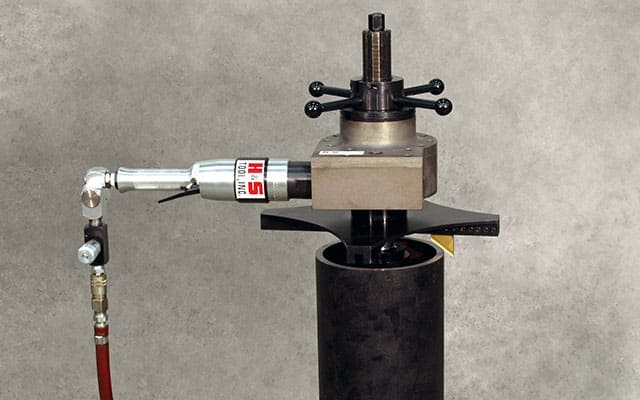

Hydraulic nuts

enable large diameter bolts to be tensioned with ease to high and accurate preloads. A hydraulic pump activates the internal jacking system, so the effort required to tighten a very large diameter bolt is reduced to the effort needed to operate the pump.As there is no nut rotation during tightening, the operation can be performed in a confined space and torsional stresses on thread damage are eliminated. Any number of hydraulic nuts can be connected together for simultaneous operation, ensuring all bolts in the joint can be evenly loaded to the same high and accurate preload.

More Information

Features

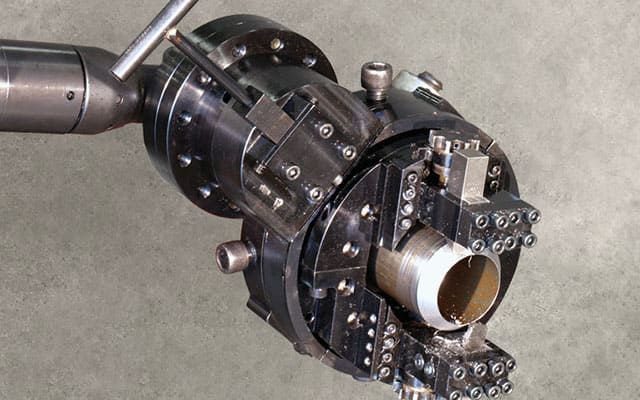

- Available as bottom collar, top collar and shim type

- Standard 1500bar and 2500bar designs

- A20/A15 range

- Substitutes original nut – combines tensioner and permanent nut

- All in one solution – nut remains in place post tensioning

- Special designs available

- Supplied up to M400 in size (to date) – larger sizes quoted

- High temperature solutions available

Advantages

- Quick and easy to install

- Even and accurate load as it is developed hydraulically

- Low loss of initial load (shim)

- No torque or torsion stress

- No flogging hammers or spanners

- Self-aligning (shim)

- Improved fatigue performance

- 100% simultaneous tension

- Long life of internal jack - very compact and cost effective

- Less stud protrusion required than for tensioners

Testing & Certification

Boltight is LRQA certified for quality and environmental assurance to ISO 9001: 2015. All tools are assembled, filled with oil and pressure tested prior to despatch.