Axial Travel: 6 or 12 inches (152.4 or 304.8 mm)

Wire Diameter Range: 0.023 – 0.045 inches (0.58 – 1.14 mm)

Step Range/Pitch: Step Range: 0.040 – 0.220 inches (1.0 – 5.6 mm)

Rotational Direction: Reversible

Auto-Skip: Auto Skip, Pie Mode & Carriage Return

Standard Torch Range: 0.50 – 54 inches (12.7 – 1371.6 mm)

HIGH QUALITY AND PRECISION

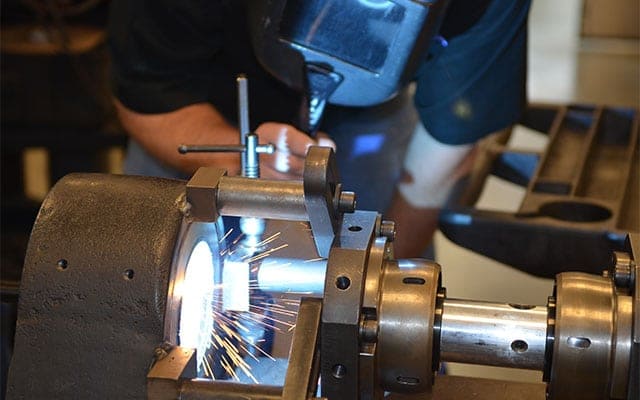

Offset head provides torch adjustment without changing the angle of the torch, always providing optimal torch angle, a key parameter for successful bore welding.Centralized control box gives the operator the ability to make changes to ALL welding parameters while closely monitoring the weld process. Quickly adjust “step” size, rotation speed, rotation direction, wire feed rate, and arc voltage; all from this one location. Arc interrupt, contactor control, gas purge and extended utilization of Auto-Skip function are also performed from the control.

Consistent and uniform weld reduces cutting tool wear, reducing cutting time by up to 50%. Infinitely adjustable step allows bead placement from 0.40 – 0.220 inches (1.0 – 5.6 mm).

Wire Feeder choices of shop style or enclosed feeders lets you select the best feeder for the application. The push pull system and wire straightener options allow welding with exotic metals or smaller cast wires.

FLEXIBLE AND VERSATILE

Auto skip feature is perfect for skipping keyways or any square area that needs to be skipped.Pie mode allows the operator to weld up localized oblong worn sections of bores quickly, saving time and weld material.

Carriage return allows operators to weld uphill or downhill only when in out of position (horizontal) orientation. This one way welding gives operators the ability to weld in a single direction, making control of the process much easier.

Reversible rotation gives the operator the ability to weld in either rotation direction. By reversing direction, the operator can weld up quality bores pass after pass more uniform and evenly.

BB5000 interface kit with spherical connection clamp collar allows quick alignment and attachment of the BW3000, shortening time between welding and boring, allowing the operator to complete jobs faster.

Adjustable mounting base allows mounting of the BW3000 to fit any workpiece when not using a boring bar. The non-magnetic mounting base makes welding in job shops, shop jobs or machine shops simple and easy.

SAFETY

Remote feed-control system allows operators to safely control the equipment from one centrally located control while keeping operators out of harm’s way, reducing hazards such as burns and dangerous fume inhalation.Emergency-Stop for immediate shutdown.

Auto-Stop allows the operator to automatically shutdown the machine at the end of the bore.