FF7200 Flange Facer

features a tool head that rotates a full 360 degrees, infinitely variable feed rates, and remotely adjustable feed so radial and axial feeds can be done quickly and safely. Facing diameters from 30 to 72 inches (762 to 1828.8 mm), milling diameters from 35 to 72 inches (889 to 1828.8 mm).

ID Facing Diameter: 11.8 – 60 inches (299.7 – 1524.0 mm)

Milling Diameter: N/A

ID Mounting Diameter: 11.8 – 57.5 inches (299.7 – 1460.5 mm)

OD Facing Diameter: 8.5 – 60 inches (215.9 – 1524.0 mm) OD Mounting Diameter: 38.1 – 63.8 inches (967.7 – 1620.5 mm) Power Option: Pneumatic or Hydraulic

IMPROVED EFFICIENCY AND OPERATIONAL FLEXIBILITY

Extended machining range, from 12 – 60 inches (304 – 1524 mm) provides more flexibility – one machine for many applications.Varible feed rate control allows operators to easily adjust the feed rate of the cutting tool.

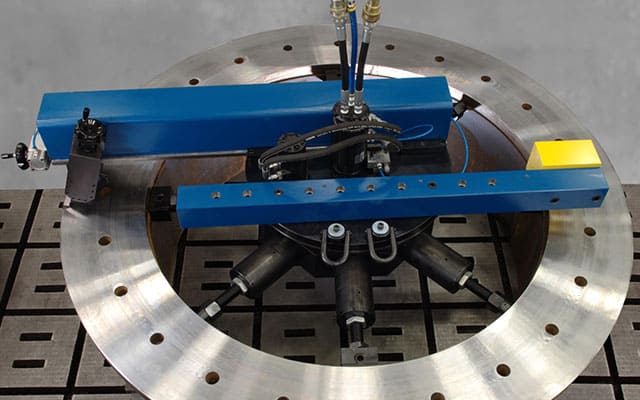

ID, OD, or surface-mount configurations are available for a variety of machining applications, with a quick and easy change over.

Chain-clamp assembly securely clamps OD-mount configurations to eliminate the need to weld for mounting.

Tool head and tool bit rotate 360˚, which allows for machining and positioning at an angle. This provides flexibility to create a variety of cuts including chamfers, O-Ring grooves, lens rings and other angular surfaces.

Back-facing attachment option provides even more flexibility in machining operations for heat exchanger tube sheets and other applications.

Modular components and overall lighter weight make setup, transport and storage quick and easy.

Hydraulic or pneumatic drive options allow flexibility for a variety of working conditions.

RUGGED DESIGN FOR POWERFUL, PRECISE MACHINING PERFORMANCE

Heavy-duty bearings provide rigid performance and reliable results, even over bolt-hole patterns.Chucking system with leveling feet allows for quick and easy setup.

Modular chuck can be mounted separate from the machine body, makes accurate setup quick & easy.

The worm gear drive system runs smoothly and provides low backlash even with interrupted cuts. High-torque power allows higher metal removal rates.

REDUCING OPERATOR RISK

Auto-feed system keeps operators hands safe from moving parts and keeps the job running smoothing.Low-pressure safety interlock system prevents unintended re-starts after the loss of supplied air pressure.

E-stop for quick stops & controlled re-starts.

Modular components are lightweight, easy-to-use, and easy-to-transport reducing the potential for worker fatigue, the number one source of accidents on many work sites. The FF5300 Flange Facer is 45% lighter than similar flange facers on the market today.

CE certified and available worldwide! All FF5300 Flange Facers are available for sale worldwide, including in the European Union and other locations where CE certification is required.