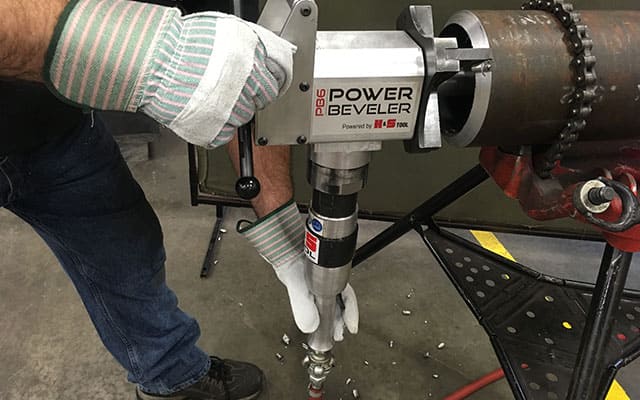

PB6 – PB12 Power Beveler

The PB6 – PB12 POWER BEVELER pipe bevelers are a combination of power, versatility, and reliability in a compact package. Designed to perform on-site machining with speed and accuracy, delivering optimal speed and torque combination to make short work of your pipe prep projects.

Model PB6

Working Range: 8 in. ID – 30 in. OD (203.2 ID – 762.0 OD mm)

Radial Tool Clearance: 24 in. (609.6 mm) & 30 in. (762 mm)

Travel: 4.5 in. (114.3 mm)

Power Option: Pneumatic (3.5 HP / 2.6 kW) or Hydraulic (10.72 HP / 8.0 kW)

Speed: 0 – 3.5 RPM, 0 – 12 RPM

Model PB8

Working Range 2 in. ID – 8.625 in. OD (50.8 ID – 219.1 OD mm)

Radial Tool Clearance 9 in. (228.6 mm)

Travel 3.5 in. (88.9 mm)

Power Pneumatic (3.0 HP / 2.2 kW),

Electric (2.5 HP / 1.9 kW),

or Hydraulic (5.36 HP / 4.0 kW)

Speed 0 – 22 RPM, 0 – 37 RPM, 0 – 40 RPM

Model PB12

Working Range 3 in. ID – 14 in. OD (76.2 ID – 355.6 OD mm)

Radial Tool Clearance 14 in. (355.6 mm)

Travel 4.5 in. (114.3 mm)

Power Pneumatic (3.0 HP / 2.2 kW),

Electric (2.5 HP / 1.9 kW),

or Hydraulic (5.36 HP / 4.0 kW)

Speed 0 – 18 RPM, 0 – 32 RPM, 0 – 40 RPM

Powerful Performance

3 Hp pneumatic motor with heavy duty gearing delivers the speed and torque to quickly cut heavy wall pipes of carbon, chrome moly, or stainless steel materials.Torque-free operation locks the machine into the pipe allowing the operator to easily run the machine without requiring additional torque restraint.

Heavy-duty tapered roller bearings for very rigid and smooth operation.

Versatility

Select from 3 models sized to bevel 6, 8 and 12 inches (152.4, 203.2 or 304.8 mm) pipe.Quick change mandrel allows the mandrel to be quickly removed from the power unit, reducing the weight.

Universal tool holder is designed to accept a variety of tooling, enabling you to perform up to three operations at the same time.

Variety of tooling options allow you to bevel, counter bore, and perform J-prep with high-speed steel or indexable carbide tooling.

Three motor options to choose from allowing you the flexibility to power the machine anywhere – pneumatic, hydraulic, and electric.

Reliability

Self-centering 3 leg wedge system centers the tool in the pipe for accurate machining.Lightweight aluminum alloy components for easy handling.

Easy grip feed handle with precision index ring makes feeding the tool to a required depth easy and accurate.

Integrated wedge system allows quick change of leg extensions.

Standard set screws allow for easy installation of the tool bits – no reaching around the tool to release the blade.

Corrosion resistant finish applied to external components prevents machine weathering.

CE Certified for use in the European Union or any country where CE certification is required.